Engineering Services

As a machine shop, we have seen many innovative machines pass through our workshop. These days, more than ever, people have great ideas for machines or tools that will make a valuable contribution to the efficiency and convenience of daily life. For some, the idea is inspired by a need or problem that requires a solution that does not yet exist. Whether it’s an idea for a new piece of furniture or an actual machine that will make production or services easier, engineering is required.

Engineering & Innovation

Innovation is the application of new technology and ideas to overcome problems and challenges. Our engineering staff are dedicated to helping our customers find the best solutions. Especially for our customers in the manufacturing sector, the proper application of engineered solutions helps them achieve their goals.

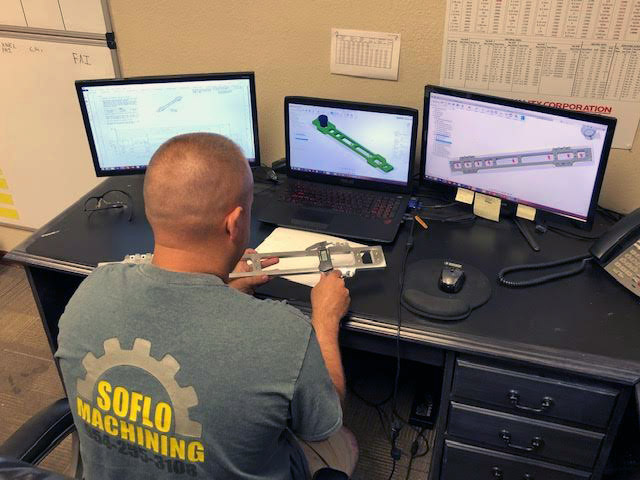

Product Design & Specification Using CAD

As mentioned, many people have ideas but lack the necessary skills to put the design down on paper or into a CAD (Computer-Aided Design) drawing. At SoFlo, our team of skilled engineers are all experienced in various software used in the design process. Allow us to listen to your requirements, and we can use the skills and expertise we have to bring the design to life. With a design in place, we can begin the process of specifying the materials and sizing. The software that we use also affords the engineers the ability to test various loads and simulate motion and areas of friction. These are useful features that help improve the final product.

Fabrication of Prototypes

Prototyping is a vital step in the production process. To test out how a machine or tool will work in the real world, building a prototype is necessary. Prototypes are utilized to sell ideas or test out a tangible version of the design idea in real-life conditions. One of the biggest advantages of prototyping is it allows you to iron out kinks and determine feasibility before committing to mass production. As part of our engineering services, we can assist with bringing your idea into the real world. With the innovative tools and machines at our disposal, we are capable of large and small prototyping jobs.

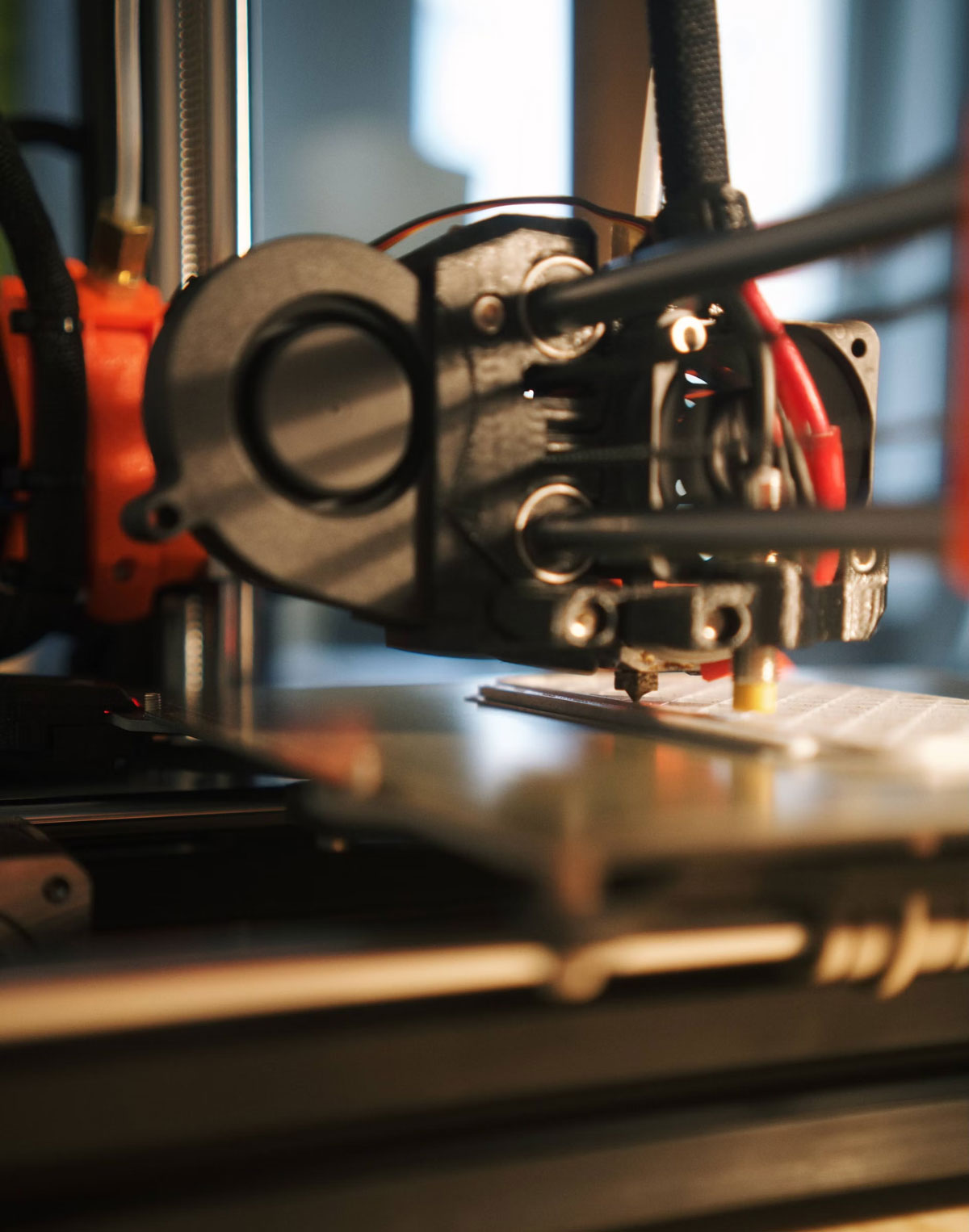

3D Printing: Small-scale and Plastic Fabrication

Our 3D printing capability enables us to develop products made from polymers as well. We have a raft of 3D printers that we use to develop smaller prototypes. Have a look at our all-inclusive equipment and capabilities page for more information.

Large Scale Machining

For all larger-scale jobs that require varying degrees of metalwork, we have the machinery to deliver what you need. Welding, laser cutting, and milling are all used in the manufacture of quality prototypes. We can weld together individual pipes or bars or use a CNC machine to mill out the design from the billet. Whatever the design calls for, we can make it happen.

Engineering Consulting Services

These days the burden of staying compliant within industry can be daunting to face without expertise in the area. Moreover, for some, it gets in the way of day-to-day production and often gets overlooked. Our machine shop can deliver here for you by way of consulting on compliance and quality control issues.

Fabrication: Custom Tools & Fixtures

When it comes to manufacturing, each production line is nuanced and unique in its way. Due to this, the perfect tool is often not available and comes bundled with a much larger, costlier solution. Often the solution required by many of our customers is only represented by a subset of the features in an off-the-shelf product. We can save you money by designing and engineering what you require according to your specifications and within budget. If you require a small fixture as a replacement, these can often be very expensive from the agents. Where possible, we can fabricate the fixture for you more cost-effectively than the manufacturer’s suggested retail price (MSRP).

3D Printing Services

Many machine shops now offer 3D printing services as an option. 3D printing allows the creation of smaller parts without using costly metals like brass, copper, steel, and aluminum. If the design will achieve its function in a plastic or gel-polymer then it can be 3D printed. Furthermore, 3D printing allows us to create small batches of parts. Good use cases for 3D printing include:

- Retaining clips

- Structural supports for lightweight material

- Sheaths and washers

- Spacers

- Replacement plastic parts for EOL products

- Retro restoration projects

- Automotive interior parts

A significant advantage of producing 3D-printed parts is the speed with which they can be produced. The manufacturing process can be easily achieved if time to market is a factor.

Nationwide Operation and Service

As our name suggests, we are based in Coral Springs, South Florida, however, we serve customers from across the United States. We hold both the ISO 9001:2015 and AS9100D certifications. Our staff are knowledgeable and experienced in dealing with manufacturing challenges and creating viable solutions.

SoFlo Engineering & Consulting Services

We have engineered solutions for customers across industries. From the medical and industrial industries to the aerospace and marine industries, we cover the full gamut of engineering challenges. If you have a goal in mind and we can help bring it to life, then we would relish the opportunity to work with you. Give us a call at (954) 255-3108 to arrange a meeting today.