CNC Machining Services

CNC machining, or computer numerical control, is a manufacturing process where computer software controls the movement of factory tools and machinery, such as lathes, mills, and routers. CNC machining allows for the manufacturing of various two and three-dimensional components and is popular when working with a billet of metals. CNC machines are not limited to metals and can also be used with wood and plastics.

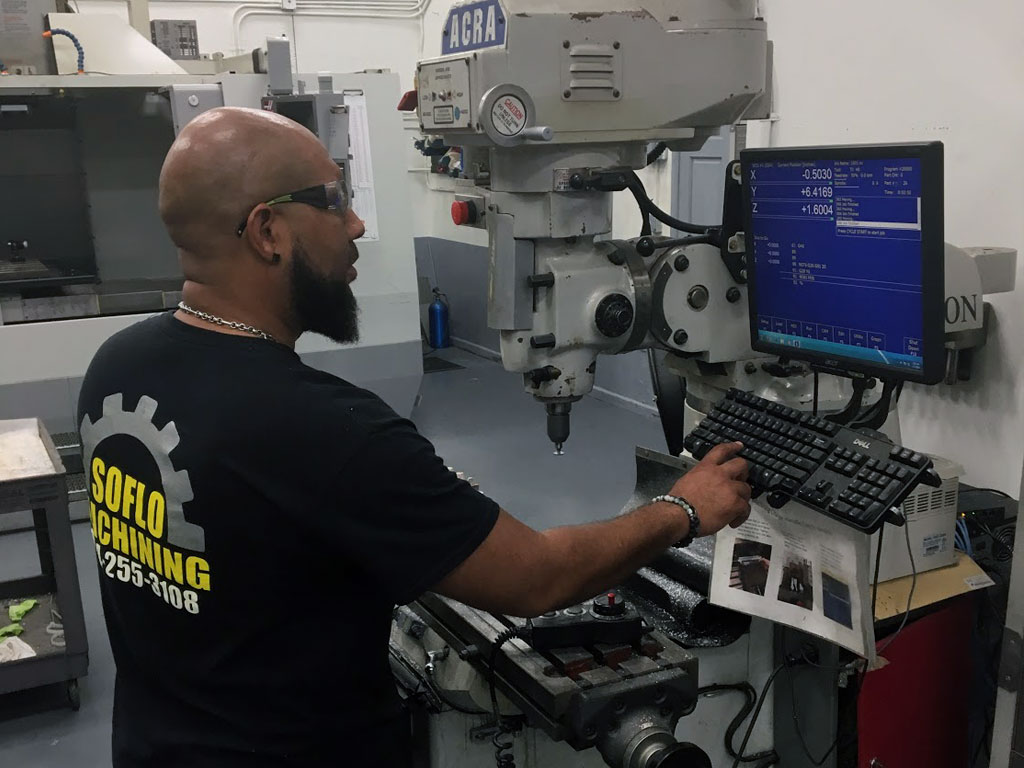

CNC Machining Services In Coral Springs

Located In Coral Springs, Florida, SoFlo Machining is a leader in the machining and manufacturing industry. We provide niche market solutions for all scales of manufacturing and have a dedicated team of knowledgeable engineers, programmers, and machinists who can assist you with any of your prototyping and manufacturing needs.

Services We Offer

We offer a variety of services to meet full manufacturing and prototyping needs. From initial CAD and CAM modeling to CNC milling, turning, cutting, welding, and finishing services such as engraving, anodizing, and surface grinding, our team can help see your project through from conception to completion.

We are also fully ISO 9001:2015 and AS9100D certified.

How CNC Machines Work

Every CNC machine works via numerical control, this is where software is used to control a specific tool. It uses a known axis, with the material positioned in a known plane of space. A 2D or 3D CAD (computer-aided design) drawing is uploaded and converted into a set of instructions that the machine can understand. From there, the software can tell the tool what movement to make and at what speed to achieve the desired action. These actions are often repetitive and move in predictable patterns, with little input needed from operators once the process has started.The Types of CNC Machines

There are a number of different CNC machines available, with every industry adapting them to meet their needs. Let’s look at some of the most common machines used in the manufacturing industry.

Lathes

Lathes operate by loading a material on a rotating mount (picture a rotisserie chicken), except for materials. As the material spins, a blade moves along the length of the material and shaves off small amounts of materials until the desired shape is achieved. Common uses for lathes include the manufacturing of engine camshafts or table legs.

Mills

Mills serve a similar purpose to lathes but can produce far more complex products. Material is loaded onto a flat tabletop, where a routing tool cuts out, drills, and shaves away material. Mills often allow for material to be shaped in all three axes.

Water Jet Cutters

Water jet cutters use a high-pressure stream of water to cut 2D shapes out of any material cleanly. Sand and other abrasives can be used to shape materials further. The benefit of waterjet is that they are capable of carving heat-sensitive materials without introducing unwanted heat to the material.

Plasma Cutters

Plasma cutters use a plasma torch to cut through materials. Plasma cutters work faster than water jet cutters but come at the disadvantage of introducing a lot of heat to the material. Plasma is produced by using electrical arcs to ignite a combination of compressed air and gas.

Laser Engraver

A laser engraver is exactly what it sounds like. It uses a concentrated beam of light to engrave detailed images onto metal. Laser engraving has become increasingly popular as it is faster than traditional engraving, removes less material, has the added benefit of not affecting rigidity, and is longer lasting than paint.

Common Materials Used in CNC Machining

At SoFlo Machining, we work on a large variety of materials, and while we are not limited to the following list, this is the most common material we work with.

- Aluminum

- Alloy Steels

- Brass

- Bronze Alloys

- Carbide

- Carbon Steel Cobalt

- Magnesium

- Stainless Steel

- Steel

- Titanium

- Tungsten

- Nickel

- Plastic

- Hastelloy

- Waspalloy

Should your project require a material not listed, please contact us to discuss how we can assist you.

Our Equipment

We don’t just talk about our capabilities, we want our clients to see what we are capable of. That’s why we openly share a full list of the machinery we have at our disposal. Our CNC machine fleet includes:

- HAAS VF6 with 5 Axis

- HAAS VF-2SSYT

- HAAS ST30

- HAAS DM-1

- Haas UMC-750SS with 5 axis

- Haas ST-15

- Kitamura 2XiF

- Edwards Jaws V Iron Worker

- Manual Mill

- Manual Lathe

- Surface Grinder

- Laser Engraving and Cutting

Additive Manufacturing Machining

What sets us apart from our competitors is our use of Additive Manufacturing Machining. Soflo Machining has developed a niche in machining features into parts that have been 3D printed. We have been making parts for defense, space, and aerospace companies.

The SoFlo Machining Difference

With 14,000 sq ft headquarters in Coral Springs, Florida, SoFlo Machining has been a marketed leader in CNC Machining for well over a decade. Trusted by the Aerospace, medical, industrial, and marine markets, with customers ranging from Lockheed Martin to Tesco Equipment LLC and Sintavia, we encourage you to visit us for all your machining needs. To arrange a meeting, please contact us at (954) 255-3108.